WE HAVE DESIGNED AND DEVELOPED A SOLUTION TO THIS PROBLEM

Maximize your undercarriage, component, and structural life

In the past ten years of field testing in different geographic areas of Saskatchewan and Alberta Canada, the results have been outstanding!

We are seeing very minimal failures with undercarriage and drive components.

The results are showing the following:

INCREASED PRODUCTIVITY

MINIMAL DOWNTIME

SUBSTANTIALLY LESS COST PER HOUR ON UNDERCARRIAGE AND DRIVE COMPONENTS

These are all factors that are very important to the contractor, to allow them to capitalize on profitability in their competitive environment.

Improve life and reduce premature track failure on the System-One and Heavy Duty Undercarriage

SCROLL DOWN TO SEE…

AFTER TEN YEARS OF FIELD TESTING, WE HAVE A SOLUTION THAT WILL SUBSTANTIALLY REDUCE YOUR OPERATING COSTS.

The problem

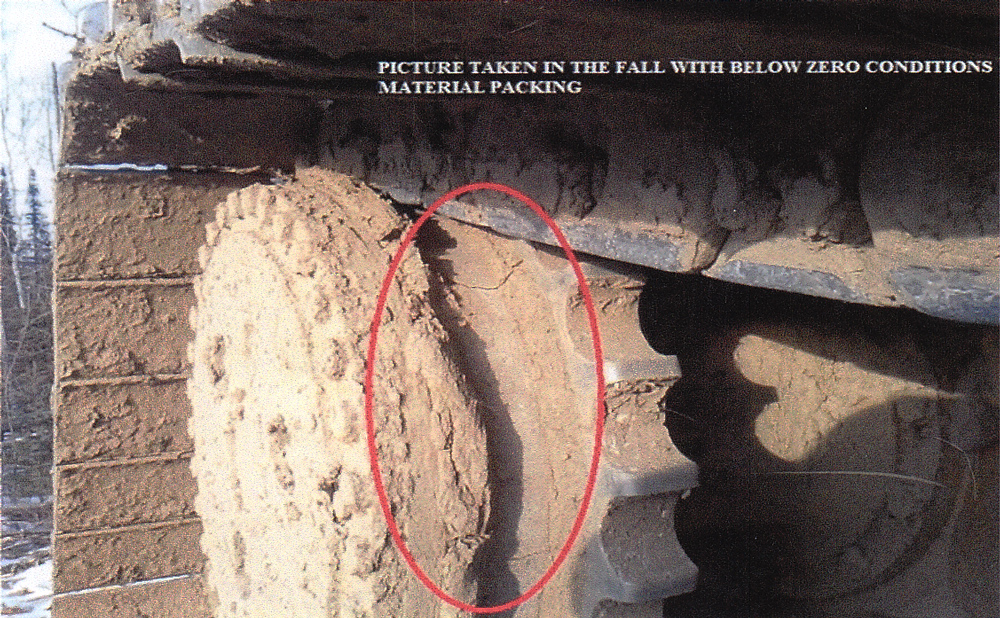

Do your tracks on a D6 or D5 Caterpillar look like this?

This picture shows what tracks look like when working in wet and/or moist soil and snow conditions. Mud and material packs between the outer flunge and the sprocket.

This then lifts the rail on one side and allows it to run off centre and also twists the link assemblies.

This will then create an off centre run pattern which minimizes the life of the link assembly.

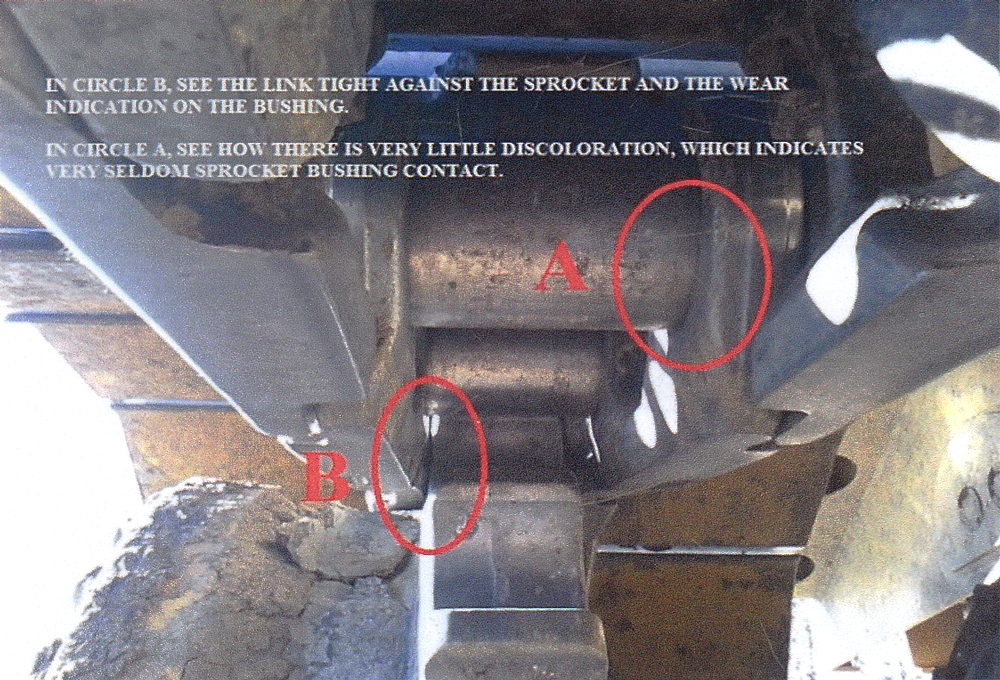

Look what happens when mud and material packs in your tracks…

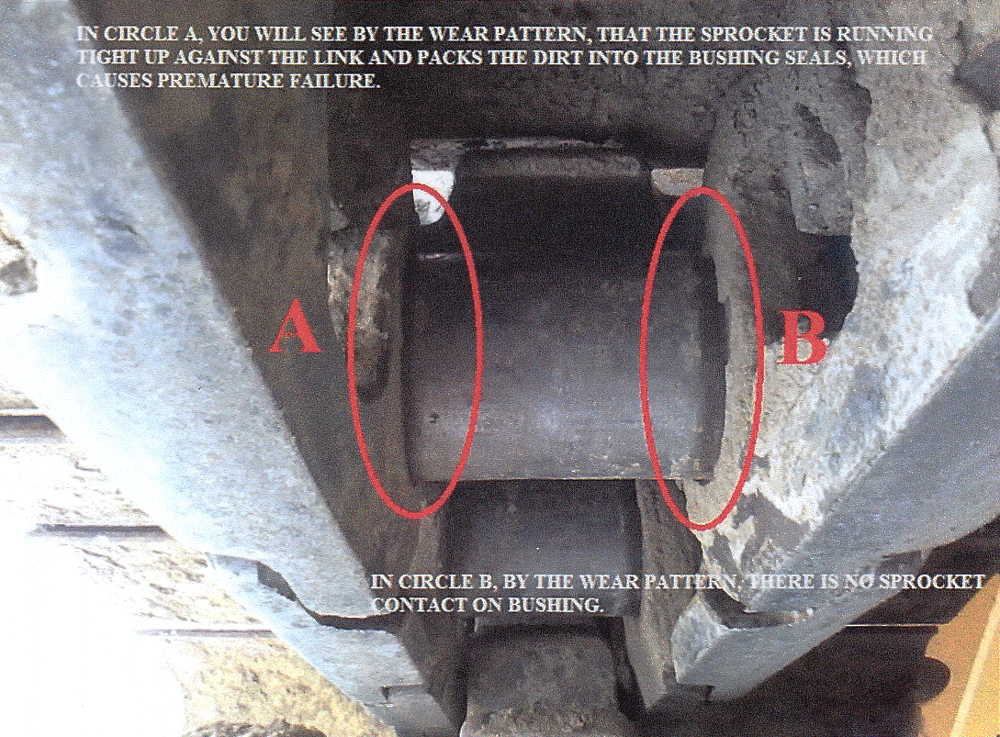

In circle A, see how there is very little discoloration, which indicates very seldom sprocket bushing contact.

In circle B, see the link tight against the sprocket and the wear indication on the bushing.

Also notice in both A and B material is packing in, lifting, and flexing the link; making the rail and sprocket contact run off center.

As you can see the rail is running off center with the sprocket shaving the inside of the link.

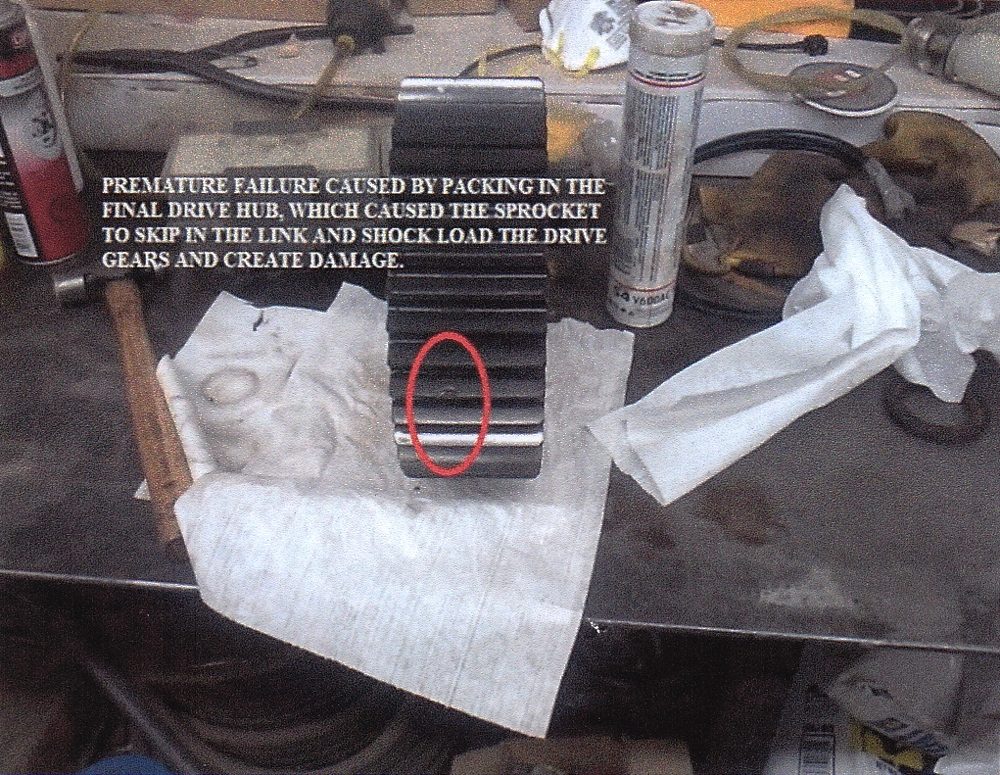

Other problems when mud and material packs in your tracks

Premature failure caused by packing in the final drive hub, which caused the sprocket to skip in the lnk and shock load the drive gears and create damage.

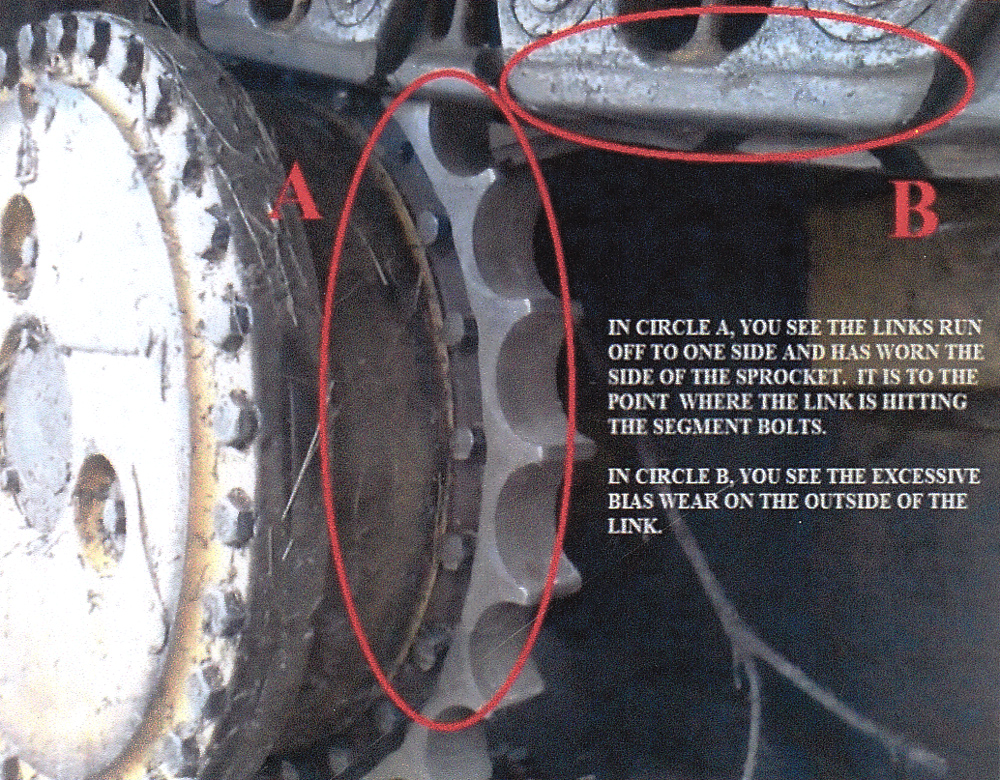

In circle A, you see the links run off to one side and has worn the side of the sprocket. It is to the point where the link is hitting the segment bolts.

In circle A, you will see by the wear pattern, that the sprocket is running tight up against the link and packs the dirt into the bushing seals, which causes premature failure.

Watch this video to see what Actually Takes Place On the Rear Drive of a Cat D6 While Working in Moist Soil, Snow or Mud

This is a real time video of what actually takes place on the rear drive of a Cat D6 while cutting and pulling ditch for a road.

It shows the material sluffing down from the outside edge of the pads, where the outside of the track link packs the material in on your drive case. It then lifts the link off away from your sprocket.

In the video you will HEAR & SEE the sprocket skip in your link. When this occurs it results in premature damage to your link assembly and shock loads the components, resulting in damaged gears, bearings and structural cracks. Also, as the links come over the sprocket, it flexes the links and allows the oil to seep. This then results in premature failure.

MATERIAL PACKED

Watch in this video how the material has packed in solid.

See how the material has packed around the drum and sprocket where it lifts the link.

It creates damage and shortens the life of the undercarriage.

The Clear Track Scraper Kit is your solution to improve the life and reduce premature track failure on the System-One and Heavy Duty undercarriage.

It is hard to create an undercarriage that can be compatible to all geographical areas in the world. However, the Clear Track Scraper Kit can be a solution to increase its cost efficiency in geographical environments that have moist soil, snow, or mud.

BENEFIT

The solution is our Clear Track Scraper Kit.

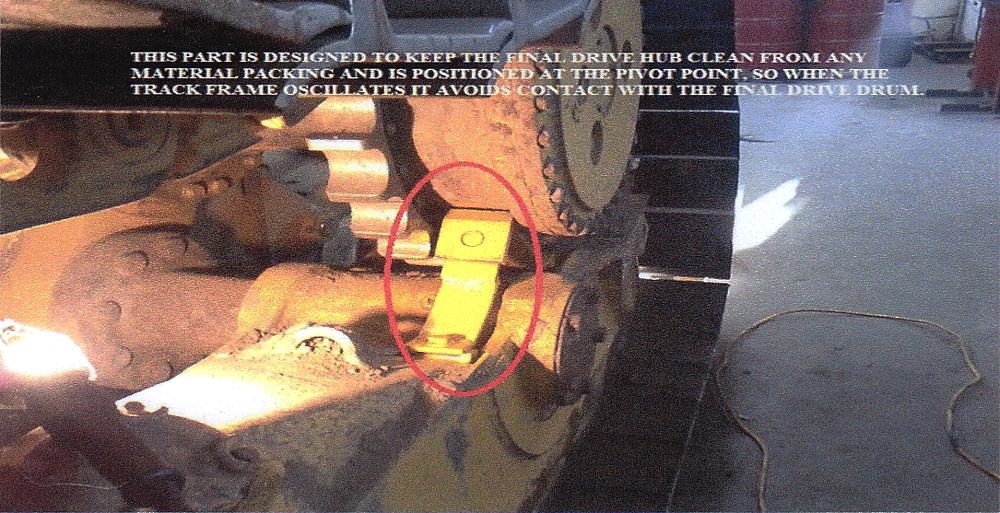

Designed to keep the final drive hub clean from any material packing and is positioned at the pivot point. So, when the track frame oscillates, it avoids contact with the final drive drum.

BENEFIT

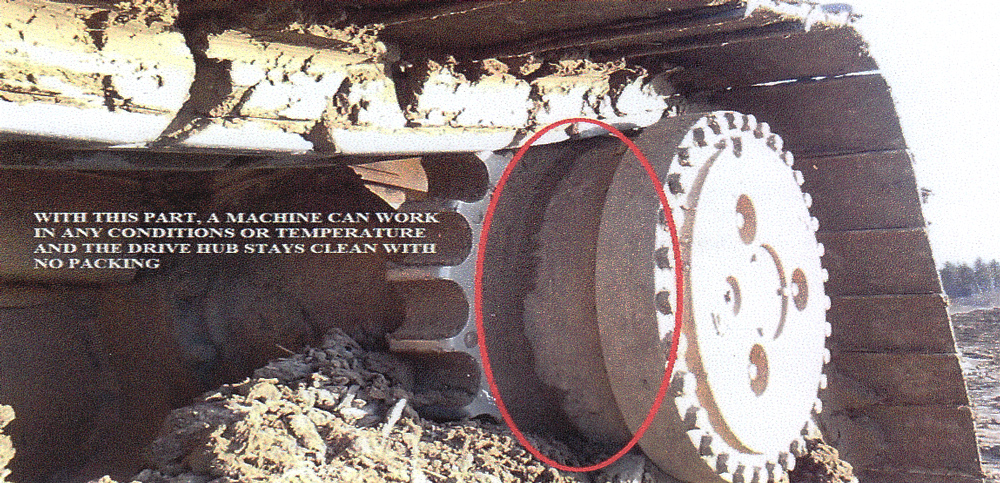

The hub stays clean with the Clear Track Scraper Kit!

The machine can work in any condition or temperature and the drive hub stays clean with no packing!

BENEFIT

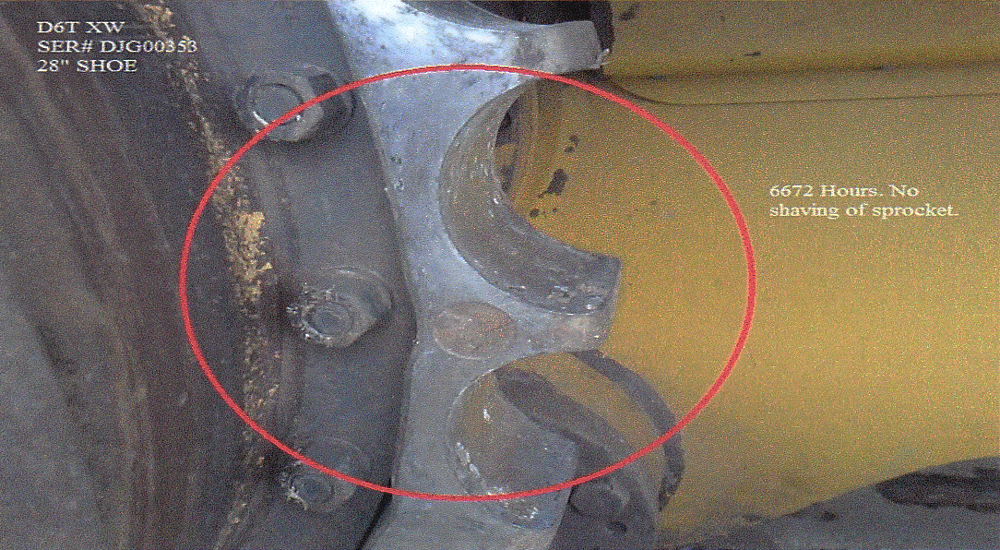

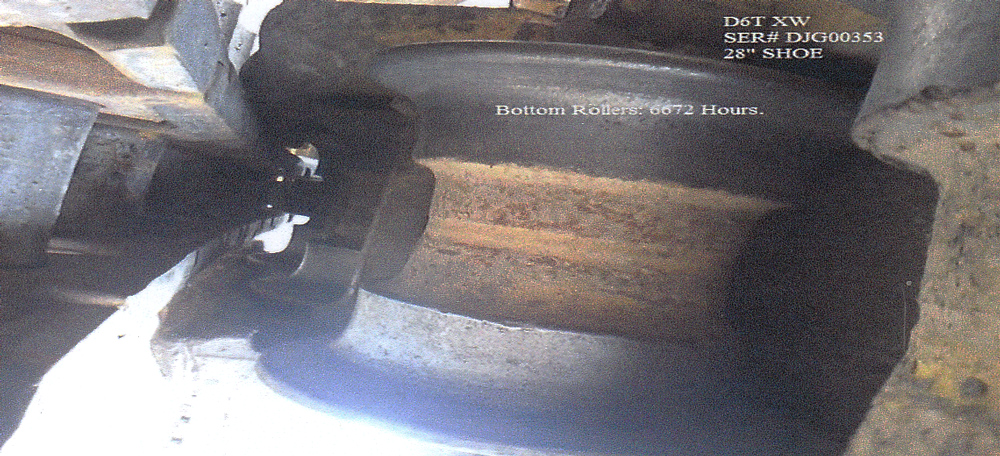

There is no shaving of the sprocket, as you can still identify the factory casting circle on the edge.

Note: D6T XW, 6672 hours, no shaving of sprocket.

BENEFIT

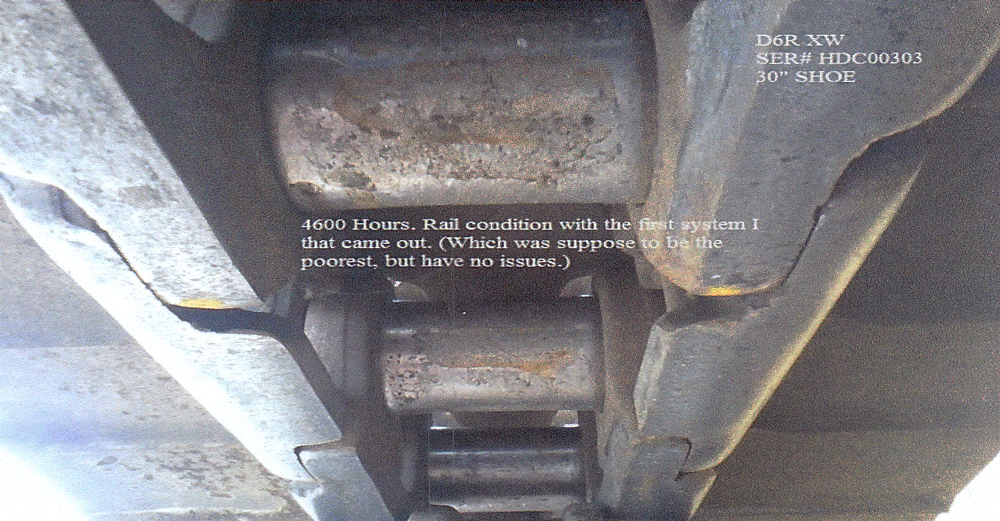

Sprocket bushing contact is even.

Note: D6R XW, 4600 hours, 30″ SHOE.

Rail condition with the first System-One.

BENEFIT

Both outer flanges are wearing evenly.

Note: D6T XW 28″ SHOE, bottom rollers: 6672 hours.

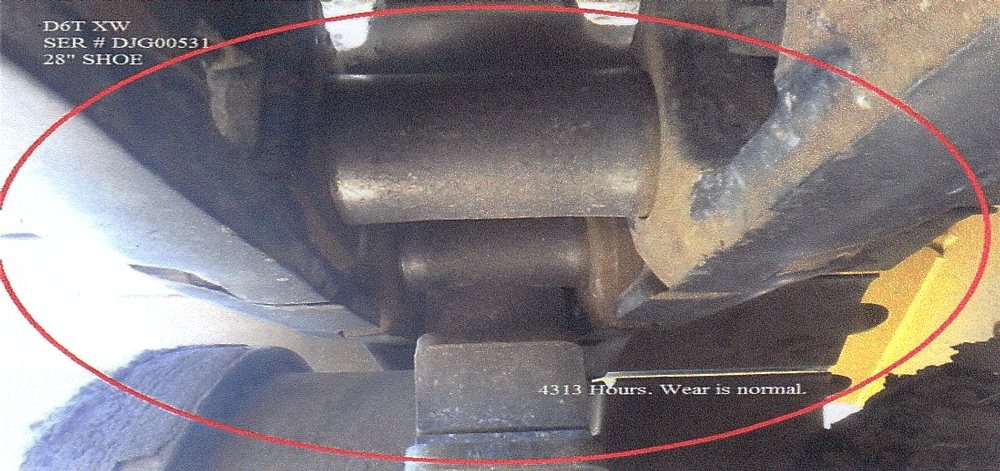

BENEFIT

Wear is normal and sprocket runs on centre.

Note: D6T XW 28″ SHOE, 4313 hours.

This undercarriage option has been tested vigorously in all types of soil and weather conditions by a number of different contractors throughout Alberta and Saskatchewan Canada.

They have experienced positive results and have indicated that they are very satisfied with adding the scraper kit option to their machines, regardless if they have System-One Undercarriage or Heavy Duty.

HAVE A QUESTION??

CALL US

ph: 1-780-808-6537

email: cincodevelopments@gmail.com

We provide fast shipping and can answer all questions you may have. For proper and precise measurements, the Clear Track Accessory Kit comes with an install procedure for fast and accurate installation.